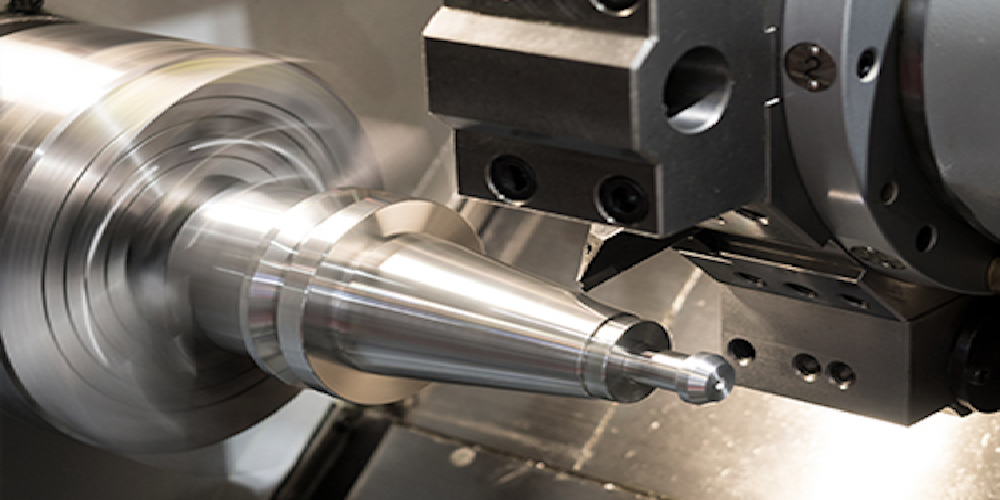

3ERP, designated as 3E Rapid Prototyping, offers demanding machining services at an industrial scale. These services mainly involve manufacturing quintessential prototypes and components showing high precision from the plastic and metal material.

The exclusive products manufactured through these outstanding services are primarily utilized for projects of industries including medical, automotive, consumer, and aerospace industries.

Main CNC Machining Services offered by the 3ERP.

Here are the main CNC machining services from 3ERP are as follows:

Rapid Tooling:

Rapid tooling allows the quick production of accurate parts that operate as a tool, mainly as a mold or a die. Injection molding is among the most common method of rapid tooling in which injection-molded parts are quickly manufactured at a budget-friendly cost.

Advantages of rapid tooling:

The service of rapid tooling offers the following advantages.

- The speedy process allows the quick finalization and manufacturing of your design and product.

- Rapid production of products saves your cost.

- It is utilized to test the process’s parameters during the production stage.

Vacuum Casting:

Vacuum casting, also called urethane casting or polyurethane casting, is a technique of creating complex components by drawing the liquid material into a silicon mold. Elastomers, namely rubber and plastics, are commonly used as liquid materials for vacuum casting. In short, it is a magnificent manufacturing process for low-volume and batch production.

Advantages of vacuum casting:

The services of vacuum casting show the following advantages.

- It allows the precise manufacturing of intricate and complex shapes.

- The simultaneous production of multiple parts can enhance production efficiency.

- It is cost-effective because of the low material price of polyurethane.

Surface finishing:

The surface finishing process changes the surface of the metal through reshaping, removal, and addition. The main purpose of surface finishing is to improve and protect the surface of the metal.

For example: In metal finishing, a coat of paint is done on the surface of the metal through powder coating or anodizing.

Advantages of surface finishing:

- Increase the aesthetic appearance and conductivity of components.

- Make the parts corrosion-resistant.

- Remove flaws and defects on the surface.

Sheet metal prototyping:

Sheeting metal prototyping services include deformation and change of the shape of a sheet of metal through drawing, stretching, and bending. It is done to form a rough draft model of your final product before the manufacturing process.

Advantages of sheet metal prototyping:

- Final parts are manufactured with higher precision.

- Reduce overall manufacturing costs because of the elimination of possible errors.

- Provide long-lasting part functionality.

Rapid metal casting:

The rapid metal casting technique integrates investment casting with 3D printing. During the processes, 3D printing techniques create disposable patterns that form molds.

Advantages of Rapid metal casting:

- It allows the manufacturing of large parts with minimal errors.

- Produce the parts with high tensile strength and dimensional accuracy.

- Gives a perfect surface finish to the final product.

Conclusion:

The machining services offered by the 3ERP are the main results behind producing accurate, precise final parts with an excellent surface finish. The above-discussed services allow the large production of high-quality parts and reduce the production cost. These machined parts are largely used on the industrial scale to manufacture long-lasting finalized products.